Once a company has determined the overhead, it must establish how to allocate the cost. This allocation can come in the form of the traditional overhead allocation method or activity-based costing.. The single overhead rate method is a simplified approach that uses a single predetermined overhead rate for all overhead costs. This is done by dividing the total estimated overhead costs by the total estimated direct labor hours or machine hours. The single overhead rate method is easy to apply but can be less accurate if the overhead costs vary significantly across different activities. By utilizing this rate, businesses can distribute overhead costs consistently across their products or services, ensuring a fair and equitable allocation.

Calculating Overhead Rates: Formulas and Examples

Following expense optimization best practices and leveraging technology keeps overhead costs in check. This aids data-driven decision making around overhead rates even for off-site owners and managers. Built-in analytics help uncover spending trends and quickly flag unusual variances for further investigation. Using small business accounting software centralizes overhead tracking and analysis.

C. Financial Reporting

Predetermined overhead cost rates are essential for timely cost allocation, budgeting, and financial reporting. Activity-based costing (ABC) is a more specific and more accurate way of assigning factory overhead to manufactured goods versus using a single factory or multiple departmental rates. An activity is a unit of work that consumes resources when performed by a company.

Predetermined Overhead Rate (POR) Formula

It is calculated by dividing the total estimated overhead costs for a period by the total estimated activity for that period. The predetermined overhead rate is an estimated rate used to allocate overhead costs to products or jobs. It is typically established at the beginning of an accounting period and is based on projected costs and activity levels. This rate helps businesses assign indirect costs efficiently rather than waiting for actual data at the end of a period. A predetermined overhead rate (OH) is a critical calculation used by businesses to allocate manufacturing overhead costs to products or services. This rate helps in budgeting, pricing, and financial planning by estimating overhead costs in advance rather than waiting for actual figures.

- Nonetheless, it is still essential for businesses to reconcile the difference between the actual overhead and the estimated overhead at the end of their fiscal year.

- Activity-based costing (ABC) is a more specific and more accurate way of assigning factory overhead to manufactured goods versus using a single factory or multiple departmental rates.

- By comparing actual overhead costs to predetermined rates, businesses can identify areas of inefficiency and make informed decisions for cost optimization.

- You’ll master the key formulas, learn how to allocate costs properly across departments, see real-world examples, and discover best practices to control overhead expenses.

- Before the start of the year, you calculate your total estimated manufacturing overhead costs.

- For example, the health-care industry may have different overhead costs and cost drivers for the treatment of illnesses than they have for injuries.

Different methods are used to apply predetermined overhead rates based on the chosen cost driver. Notice that the formula of predetermined overhead rate is entirely based on estimates. The overhead applied to products or job orders would, therefore, be different from the predetermined overhead rate formula actual overhead incurred by jobs or products.

The tool is especially useful in manufacturing and production settings, where accurate cost allocation is critical for job costing and financial planning. It ensures that overhead expenses are fairly distributed across jobs or products, aligning costs with resources consumed. The most prominent concern of this rate is that unearned revenue it is not realistic being that it is based on estimates. Since the numerator and denominator of the POHR formula are comprised of estimates, there is a possibility that the result will not be close to the actual overhead rate. The fact is production has not taken place and is completely based on previous accounting records or forecasts.

- Hence, this predetermined overhead rate of 66.47 shall be applied to the pricing of the new product VXM.

- For example, direct labor hours or machine hours can be used as the measure of activity.

- This is calculated at the start of the accounting period and applied to production to facilitate determining a standard cost for a product.

- Upon completion, earn a prestigious certificate to bolster your resume and career prospects.

- So, for every machine hour you clock while manufacturing your furniture during the year, you would apply $25 of your estimated overhead costs to that product.

Common activity bases include units of output, machine-hours, and direct labor-hours. The management of Parker Company would like to use activity-based costing to allocate overhead rather than use one plantwide rate based on direct labor hours. The following estimates are for the activities and related cost drivers identified as having the greatest impact on overhead costs. Determine the predetermined overhead rate by dividing the total estimated overhead costs by the estimated activity level.

Upon completion, earn a prestigious certificate to bolster your resume and career prospects. For every hour a line worker records directly creating a purse, we allocate $10 in fixed overhead to that item. For every hour a machine runs, we allocate $4 in fixed overhead to that item. Companies that produce several different products may believe that the benefits of implementing ABC will outweigh the costs. However, management must be willing to use the ABC information to benefit the company. Companies like Chrysler Group LLC have been known to try ABC, only to meet resistance from their managers.

- Therefore, at the end of the period, there might be an underapplied or overapplied overhead, which must be adjusted.

- Understanding these formulas allows businesses to budget for overhead, set predetermined rates, analyze variances, and adjust rates accordingly.

- This calculator simplifies the process by requiring just a few inputs, such as total estimated overhead costs and the total estimated base (e.g., labor hours or machine hours).

- A cost pool is a list of costs incurred when related activities are performed.

- This aids data-driven decision making around overhead rates even for off-site owners and managers.

It would involve calculating a known cost (like Labor cost) and then applying an overhead rate (which was predetermined) to this to project an unknown cost (which is the overhead amount). The formula for calculating Predetermined Overhead Rate is represented as follows. It is unlikely that one rate can capture all the diversity of what goes on in a factory with reliable precision. As you can see in Figure 3.6 “SailRite Company Product Costs Using Activity-Based Costing”, overhead is a significant component of total product costs. This explains the need for a refined overhead allocation system such as activity-based costing. As you can see in Figure 3.6, overhead is a significantcomponent of total product costs.

- Commonly, the manufacturing overhead cost for machine hours can be ascertained from the predetermined overhead rate in the manufacturing industry.

- Predetermined overhead cost rates are calculated estimates used to allocate overhead costs to products or services based on a chosen cost driver, such as labor hours, machine hours, or production volume.

- In this article, we will discuss the formula for predetermined overhead rate and how to calculate it.

- As you’ve learned, understanding the cost needed to manufacture a product is critical to making many management decisions (Figure 6.2).

- Keeping overhead costs in check can have a notable impact on the bottom line.

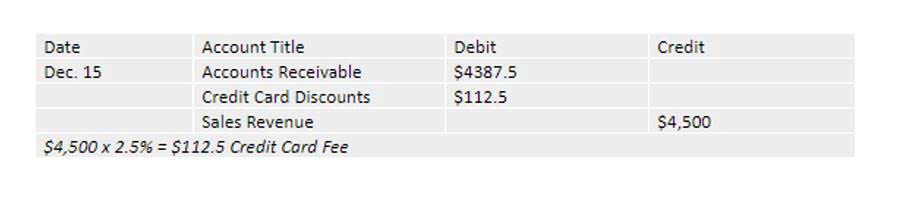

The comparison of applied and actual overhead gives us the amount of over or under-applied overhead during the period which is eliminated through recording appropriate journal entries at the end of the period. Suppose GX company uses direct labor hours to assign manufacturing overhead cost to job orders. The company’s budget shows an estimated manufacturing overhead cost of $16,000 for the forthcoming year. The company estimates that 4,000 direct labors hours will be worked in the forthcoming year. Activity-based costing (ABC)4 usesseveral cost pools, organized by activity, to allocate overheadcosts. Thus the cost Online Bookkeeping ofactivities should be allocated to products based on the products’use of the activities.